As power electronics evolve into more compact, high-efficiency architectures, the demands on thermal management escalate. From electric vehicle controllers to smart grid converters, today's systems operate under intensified thermal and electrical stress. Maintaining thermal equilibrium is no longer optional—it's critical to both safety and performance.

Diode NTC thermistors, a hybrid solution combining temperature sensitivity and rectifying behavior, are now stepping into the spotlight. They offer a fusion of thermometric precision and electronic functionality, particularly suited for environments where space, efficiency, and reliability are paramount.

2. Understanding Diode NTC Thermistors

2.1 What Makes a Diode NTC Thermistor Unique?

A diode NTC thermistor is essentially a Negative Temperature Coefficient thermistor configured with diode-like electrical properties. This means its resistance decreases predictably as temperature rises, while also exhibiting a unidirectional current flow behavior. This duality allows it to function as both a temperature sensor and a protective component in DC circuits.

2.2 Key Electrical Characteristics and Behavior

These devices demonstrate a steep resistance drop across a defined thermal gradient, with high sensitivity to minute temperature changes. Electrically, their diode-like response restricts reverse voltage exposure—protecting adjacent circuitry. They also offer low thermal inertia, enabling rapid response in dynamic thermal environments.

3. The Role of Diode NTC Thermistors in Power Electronics

3.1 Mitigating Inrush Current in High-Power Circuits

Inrush current—the initial surge when a circuit is energized—can wreak havoc on power systems. Diode NTC thermistors suppress this phenomenon by initially presenting high resistance, then gradually reducing it as they heat. This self-regulating behavior absorbs the shock of startup current, safeguarding MOSFETs, capacitors, and transformers.

3.2 Enhancing Component Longevity Through Temperature Regulation

Thermal cycling, if left unchecked, accelerates component degradation. By continuously monitoring and reacting to temperature shifts, diode NTC thermistors help maintain optimal operating conditions. This stability extends the service life of heat-sensitive components such as IGBTs, high-frequency inductors, and voltage regulators.

4. Applications in Battery Pack Systems

4.1 Real-Time Temperature Monitoring in Lithium-Ion Packs

In lithium-ion battery modules, overheating is a silent saboteur. Diode NTC thermistors provide real-time thermal feedback at the cell level. Their swift response curve ensures dangerous spikes are detected before reaching critical thresholds—essential in EVs, drones, and energy storage systems (ESS).

4.2 Integration into Battery Management Systems (BMS)

Modern BMS architectures leverage diode NTC thermistors as frontline temperature sensors. Their directional conductivity allows for noise-immune signal transmission, reducing false readings caused by electromagnetic interference. Integrated seamlessly with microcontrollers, these thermistors drive automated cooling, cell balancing, and shutdown protocols.

5. Advantages Over Conventional Thermistors

5.1 Built-in Redundancy and Circuit Simplification

Unlike conventional thermistors requiring additional protection diodes, diode NTC variants offer integrated redundancy. This consolidation reduces PCB real estate and component count—crucial for portable or high-density applications. Fewer parts mean fewer potential failure points.

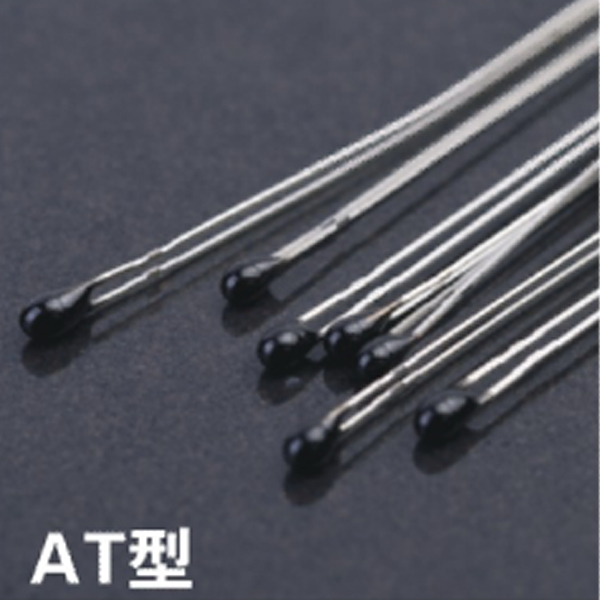

5.2 Compact Design for Space-Constrained Environments

Thanks to their hybrid functionality, diode NTC thermistors can be fabricated in ultra-compact SMD or glass-encapsulated formats. This makes them ideal for densely packed modules such as smartphone batteries, medical wearables, or aerospace-grade power supplies where every millimeter matters.

6. Selecting the Right Diode NTC Thermistor for Your Application

6.1 Important Parameters to Consider

Choosing the ideal thermistor involves more than resistance values. Designers must evaluate beta coefficient, thermal time constant, voltage rating, and power dissipation capacity. Matching these parameters to system requirements ensures accurate sensing and reliable protection.

6.2 Customization Options from Advanced Manufacturers

Leading thermistor manufacturers now offer bespoke solutions tailored to specific thermal profiles. From encapsulation materials to lead configurations and tolerance ranges, engineers can specify every detail. This level of customization ensures that each component aligns with the unique demands of its host system.

7. Conclusion

As the electrification of industries accelerates, so too does the need for smarter thermal solutions. Diode NTC thermistors offer a resilient, multifunctional answer to the challenges faced by power electronics and battery pack engineers. Through their compactness, responsiveness, and integrative potential, these components are quietly becoming essential enablers of safe, stable, and efficient energy systems.