In electronics manufacturing, precision and efficiency are key. One essential tool that meets these demands is the wire and chip soldering machine. This equipment simplifies the soldering process for both wires and chips, ensuring consistent quality while saving time and labor. For manufacturers looking to enhance production capacity without compromising accuracy, investing in a reliable soldering machine is a smart move.

What is a Wire and Chip Soldering Machine?

A wire and chip soldering machine is a specialized device designed to automate the soldering of wires and electronic chips. These machines can handle various wire types and chip sizes, delivering precise soldering connections that are crucial for electronics assembly. They range from fully automatic systems to semi-automatic models, depending on the production needs and budget.

By combining mechanical precision with user-friendly controls, these machines reduce the risk of human error, improve workflow consistency, and maintain high-quality standards across every product.

Full Automatic Single/Twin Wire Chip Soldering Machine

Advantages of Using Wire and Chip Soldering Machines

Investing in a wire and chip soldering machine offers multiple benefits for electronics manufacturers:

1. High Efficiency

Machines like Horle’s semi-automatic twin wire and chip soldering machine can process up to 3800 pieces per shift. This speed allows manufacturers to meet tight deadlines without sacrificing soldering quality, which is particularly useful for high-volume production.

2. Precision Soldering

Manual soldering can lead to inconsistent connections, which may compromise the performance of electronic devices. A dedicated soldering machine ensures every wire and chip is connected with accuracy, reducing defects and enhancing product reliability.

3. Cost-Effective Production

By automating soldering tasks, manufacturers save on labor costs while reducing material waste caused by errors. This efficiency makes wire and chip soldering machines an economical choice for both small-scale and large-scale production.

4. Versatility

Modern soldering machines support a wide range of wire types and chip sizes. This versatility allows manufacturers to use a single machine for different projects, minimizing equipment costs and production downtime.

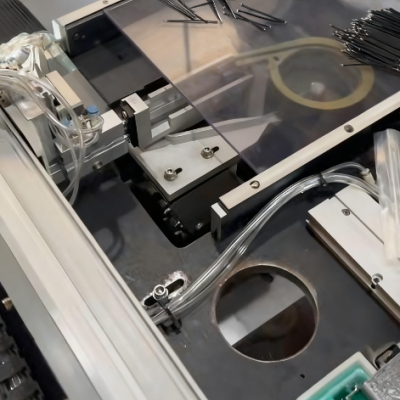

Semi-Automatic Twin Wire And Chip Soldering Machine

Semi-Automatic Twin Wire and Chip Soldering Machine by Horle

Horle offers a semi-automatic twin wire and chip soldering machine that combines efficiency, precision, and ease of use. Designed for manufacturers seeking a reliable soldering solution, this machine stands out for its ability to handle twin wires and chips simultaneously, optimizing production flow.

Key features include:

- High Output: Capable of soldering 3800 pieces per shift.

- Precision Soldering: Ensures consistent and accurate connections for wires and chips.

- Cost Efficiency: Reduces labor and material waste while improving production speed.

- Versatility: Suitable for a variety of wire types and chip sizes.

This machine is ideal for electronics assembly lines that require both quality and speed. Its semi-automatic design offers a balance between automation and control, making it accessible for manufacturers of all sizes.

Applications in Electronics Assembly

Wire and chip soldering machines are widely used across electronics manufacturing, including:

- Consumer electronics, such as smartphones and home appliances.

- Automotive electronics, including wiring harnesses and control units.

- Industrial electronics, such as sensors and circuit boards.

By automating soldering tasks, manufacturers can ensure high-quality connections, reduce rework, and maintain consistency across complex electronic assemblies.

Choosing the Right Wire and Chip Soldering Machine

When selecting a wire and chip soldering machine, consider:

- Production Volume: Match the machine’s capacity to your manufacturing needs.

- Wire and Chip Types: Ensure compatibility with the wires and chips used in your products.

- Efficiency: Look for machines that balance speed with precision.

- Ease of Use and Maintenance: Machines that are simple to operate and maintain minimize downtime and training costs.

Horle’s semi-automatic twin wire and chip soldering machine addresses all these factors, offering a reliable and versatile solution for modern electronics assembly.

Conclusion

A wire and chip soldering machine is an investment that can significantly improve electronics production. By enhancing soldering precision, boosting efficiency, and reducing labor costs, these machines support manufacturers in producing high-quality products at scale.

Horle’s semi-automatic twin wire and chip soldering machine provides an ideal solution for companies seeking reliability, versatility, and cost-effective performance. For manufacturers looking to streamline their assembly processes and achieve consistent results, Horle offers machines that meet both production and quality standards.

Explore Horle’s range of wire and chip soldering machines today and take the next step toward smarter, faster, and more precise electronics assembly.