Quick Selection Summary:

- PTFE: Best for extreme heat (260°C) and chemical resistance. Requires etching for potting.

- FEP: Best for long cable runs and transparency. Similar to PTFE but melt-processable.

- PFA: The "High-Temp FEP." Combines PTFE's heat resistance with FEP's flexibility.

- ETFE: Best for mechanical strength. Tough, abrasion-resistant, ideal for robotics and aviation.

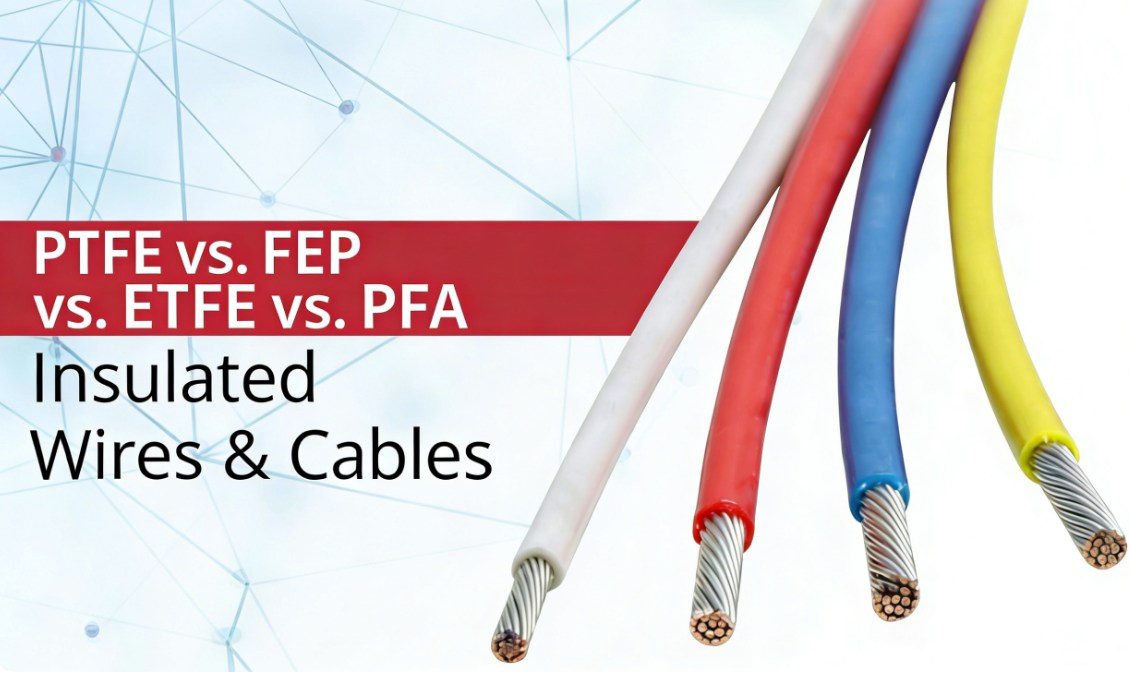

In the world of high-performance cabling—whether for medical catheters, aerospace sensors, or automotive harnesses—standard PVC insulation simply melts away. This is where the Fluoropolymer family dominates.

Often grouped under the umbrella term "Teflon" (a Chemours trademark), these materials—PTFE, FEP, PFA, and ETFE—offer unmatched thermal stability and chemical inertness. But for a procurement manager or engineer, choosing the wrong one can mean production failures or overpriced BOMs.

This guide breaks down the "Insulation Battle" to help you select the exact wire for your application.

The Fluoropolymer Family: An Overview

Fluoropolymers are plastics containing carbon-fluorine bonds, which are among the strongest in organic chemistry. This gives them three superpowers:

- High Temperature Resistance: Operating from 150°C to 260°C.

- Chemical Inertness: Impervious to acids, solvents, and fuels.

- Dielectric Strength: Excellent electrical insulation even in thin layers.

But not all fluoropolymers are created equal. Let's compare the four titans.

PTFE (Polytetrafluoroethylene): The Heat King

PTFE is the original fluoropolymer. It is the most common insulation for high-end electronics due to its supreme thermal range.

- Temperature Rating: 260°C.

- Key Trait: It does not melt; it sublimes. This means it cannot be extruded like normal plastic. It must be sintered (pressed from powder), which makes it more expensive to manufacture but incredibly stable.

The "Non-Stick" Problem: Why You Need Etched PTFE Wire

PTFE is famous for being "non-stick" (think frying pans). In wire manufacturing, this is a nightmare.

- The Issue: If you try to encapsulate a standard PTFE wire into a sensor housing using epoxy or glue, it will not stick. The epoxy will cure, but the wire will slide right out, causing seal failure and moisture ingress.

- The Solution: Etched PTFE Wire. Chemical etching (using a sodium-naphthalene solution) strips fluorine atoms from the wire's surface, leaving a rough, carbonaceous layer. This brown texturing allows adhesives, potting compounds, and molding resins to bond permanently to the insulation.

- Target Application: NTC Thermistors, medical probes, and oil & gas sensors requiring hermetic seals.

View Our Etched PTFE Wire Solutions

FEP (Fluorinated Ethylene Propylene): The Clear Processor

FEP was developed as a "melt-processable" version of PTFE.

- Temperature Rating: 200°C.

- Key Trait: Unlike PTFE, FEP can be melted and extruded in long, continuous lengths. This makes it faster and slightly cheaper to produce.

Why Choose FEP?

- Transparency: FEP is clearer than PTFE (which is opaque white). This is vital for medical applications where visual inspection of the internal conductor is required.

- Long Lengths: Ideal for long cable runs where the batch processing of PTFE is inefficient.

- Flexibility: Slightly softer than PTFE, making it easier to route in tight spaces.

PFA (Perfluoroalkoxy): The Best of Both Worlds

Think of PFA as the "Super FEP." It combines the processing ease of FEP with the thermal performance of PTFE.

- Temperature Rating: 250°C (Matches PTFE).

- Key Trait: High-temperature melt processability.

The Silver Coated Nickel PFA Wire Advantage

When you combine PFA insulation with a Silver Coated Nickel conductor, you get a wire that is virtually indestructible in industrial environments.

- Application: Semiconductor manufacturing equipment and downhole oil drilling tools where 250°C heat is constant, but the wire needs to be tough and flexible.

ETFE (Ethylene Tetrafluoroethylene): The Mechanical Tank

ETFE (often known by the brand name Tefzel™) is the odd one out. It is a copolymer, meaning it sacrifices a little heat resistance for massive gains in strength.

- Temperature Rating: 150°C-200°C

- Key Trait: Mechanical Toughness. ETFE is significantly stiffer and more resistant to abrasion, cuts, and radiation than PTFE, FEP, or PFA.

Why It’s the "Anti-Tear" Choice

In robotics or aviation, wires rub against metal frames. Soft PTFE might wear through, causing a short circuit. ETFE is hard and durable. It is the standard for airframe wiring and nuclear plant instrumentation due to its radiation resistance.

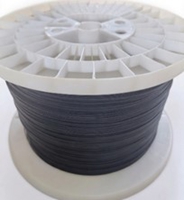

The Twin Wire Revolution: Twin Teflon, ETFE, & FEP

In the sensor industry, single wires are often annoying to manage. Enter Twin Wire (Parallel Wire).

What is Twin Wire?

Instead of twisting two separate wires together, Twin Wire is extruded as a single figure-8 shape. The two conductors are parallel and insulated together, but can be separated (zipped) at the ends.

Why Use Twin Wire for NTC Sensors?

- Space Saving: Twin Teflon Wire or Twin FEP Wire is flatter than twisted pairs, allowing it to fit into narrower sensor housings (like medical catheters or battery probes).

- Consistency: The capacitance between the two conductors is uniform along the entire length, which is critical for precision signal measurement.

- No Unraveling: Unlike twisted pairs that can unravel at the cut end, Twin Wire stays neat, making automated stripping and soldering much faster.

Comparison Matrix: The Insulation Battle

| Feature | PTFE | FEP | PFA | ETFE |

| Max Temp | 260°C | 200°C | 250°C | 150°C-200°C |

| Process | Sintering (Ram Extrusion) | Melt Extrusion | Melt Extrusion | Melt Extrusion |

| Abrasion Resistance | Fair | Fair | Good | Excellent |

| Flexibility | High | High | High | Medium (Stiff) |

| Clarity | Opaque | Clear | Clear | Translucent |

| Bondability | Requires Etching | Difficult | Difficult | Good |

| Cost | High | Medium | Very High | Medium |

Conclusion: Which Fluoropolymer Wins?

The winner depends entirely on your failure point:

- If your failure point is Heat (>200°C): Choose PTFE or PFA. Use Etched PTFE if you need to glue/pot the wire.

- If your failure point is Mechanical Wear: Choose ETFE. It is the toughest wire on the market.

- If your failure point is Cost/Processability: Choose FEP. It offers 80% of PTFE's performance at a lower price point and is great for see-through applications.

- If you need compact sensor wiring: Switch to Twin Teflon or Twin FEP to save space and improve assembly speed.

At Horle, we stock the complete spectrum of fluoropolymer wires. From Etched PTFE for hermetic sensors to Silver Coated Nickel PFA for extreme industrial use, we can cut, strip, and customize wire to your exact engineering needs.

Need a sample kit to test flexibility and bondability?

Explore the Full Cable & Wire Catalog and Contact Us for a Free Wire Sample Kit.